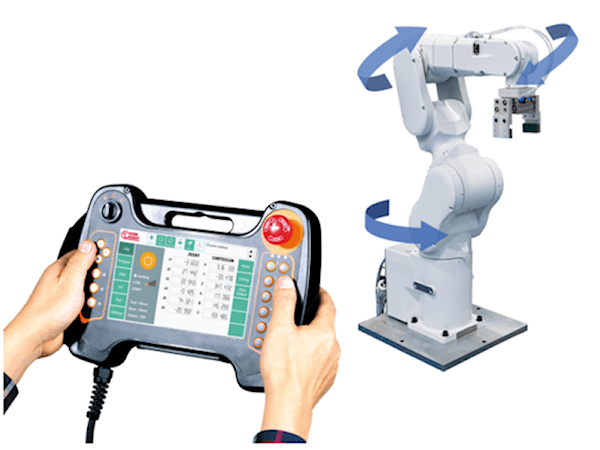

Optimized for Industrial Robots.

DTP7H-coreCon

Motion Controller

Motion Controller (DMC-coreCon)

Reduced Development Time - Immediate deployment with simple configuration, no programming required.

Custom Optimization - Supports development and application of customized robot kinematics.

Integrated Control - Unified management of diverse robots through a single UI.

Easy Expansion - API library enables integration with higher-level systems.

Broad Compatibility - Seamless integration with EtherCAT servo drives from various manufacturers.

Simplified Wiring - Minimizes complex wiring for easy installation and maintenance.

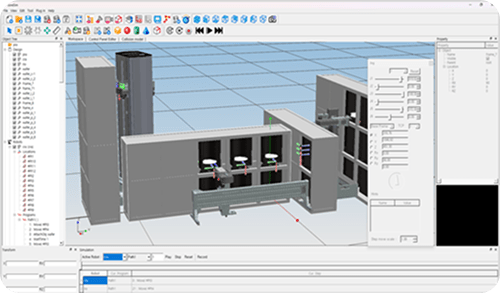

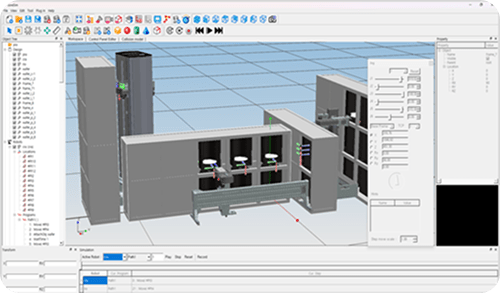

CoreSim - 3D Model-Based Simulator

Offline programming enables pre-verification without actual equipment: collision detection / cycle time analysis / layout validation. Reduces training, testing, and maintenance costs.

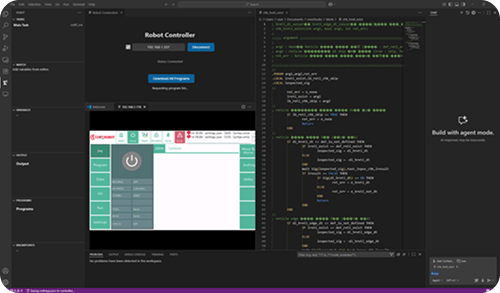

CoreStudio – A More Powerful and Smarter Development Environment

CL script IntelliSense, AI code recommendations, and automation. Remote debugging and data management. An all-in-one solution for efficient development and rapid validation.

Custom Kinematics

Daincube's motion controllers support not only standard robot kinematics (Cartesian, Serial, SCARA, Delta, UR6, etc.), but also custom kinematic structures desired by customers.

Virtual Axis

Virtual axes can be created independently of physical axes. Complex multi-joint structures can be integrated into simple logical axes → Simplified control algorithms.

Hint Function

In multi-arm environments, select operation modes by specifying constraints for each arm as Custom Hints (e.g., maintain relative angle, maintain specific position). This enables predictable and stable control of complex multi-joint structures.

Cofactor (Linkage Axis Compensation)

Mathematically compensate mechanically linked axes.

Vibration Reduction Function

The Daincube motion controller provides various vibration suppression functions to reduce residual vibration in equipment occurring within precision motion control environments. These functions support stable performance when robots and automation equipment perform high-speed, high-precision operations.

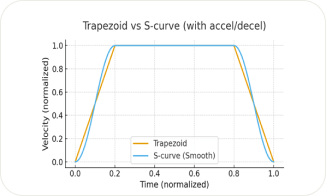

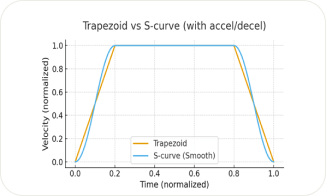

Smooth (S-curve)

Creates smooth acceleration/deceleration sections using an S-curve to mitigate shock and residual vibration

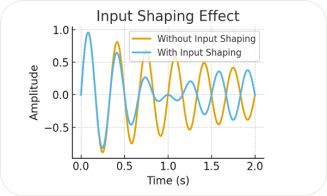

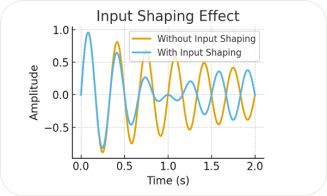

Input Shaping Filter

Pre-corrects command inputs to minimize resonant frequency (structural vibration) components

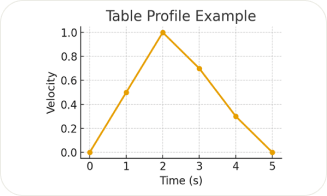

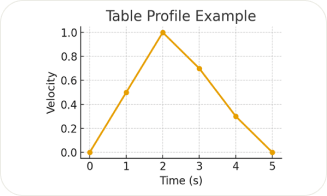

Table Profile

Optimizes process/structural characteristics using a user-defined profile based on a time-velocity table

Controller Advantages

Logging

- System / Operation / Driver Log

- TCP / MCProtocol / Modbus Communication Log

- NVRAM Debug Logging → Safe Recovery after Power Failure

Diagnostics

- EtherCAT Diagnostics: Cycle/Shift/Sync, Lost Frame, Working Count

- Slave Status / Bus Topology / Link Down Logging

- Axis Status: Servo On/Off, OP/Link Verification

Debugging

- Check Mode: Step-by-step safety verification

- Breakpoint & Watch View: Variable monitoring

- Debug Mode: Conveyor/Signal testing

- NVRAM Debug Logging → Safe recovery after power failure

Profile Analysis

- Chart Function: 5000-cycle recording/analysis

- Position / Velocity / Torque Comparison

- Frequency/Time Domain Analysis → Vibration & Tracking Error Verification

- Tuning · Performance Optimization · Anomaly Pattern Analysis

Simulation & UX

- The Dryrun feature enables safe and rapid pre-installation verification by executing program logic without driving actual equipment.

- Digital twin simulation integrated with 3D model-based coreSim enables pre-optimization of collisions, cycle times, and layouts.

- Custom UI API allows implementation of a customized UI reflecting the customer's identity.

Technical info

CPU

i.MX6Q:Quad 1.0GHz

Cortex-A9 Core (11500 DMIPS)

Display

7″

1024 x 600 resolution

Switch

Emergency stop, Select,

3 level Enabling

Memory

DDR3 800MHz 1GB

OS

Embedded Linux 4.1.15

Real-time Linux (Xenomai) 2.6.5

Qt 4.8.7

EtherCAT Master 1.5.2

File System ext4

Dimension

270x195x72mm

Storage

eMMC 8GB (MLC type)

MRAM 2MB (Option)

Interface

EtherCAT, Ethernet,

RS-485

Weight

1000g (Without Cable)

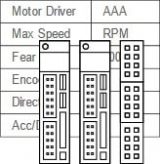

Setting & Configuration

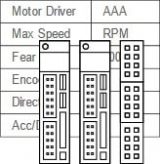

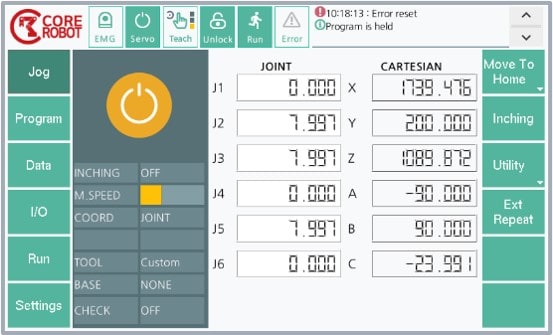

1. Quick Setting

Select Robot Type

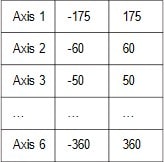

Driver Spec

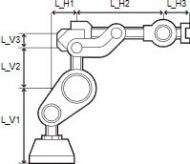

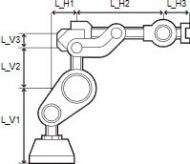

Dimension

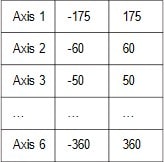

Work Range

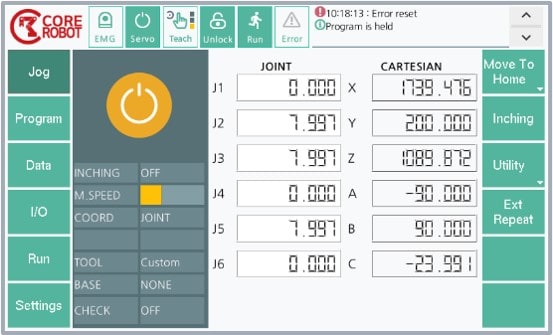

Jog

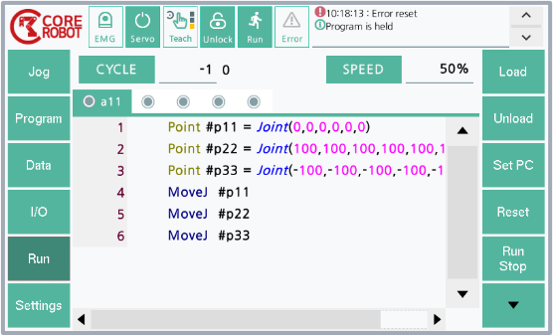

2. Jogging (Teaching)

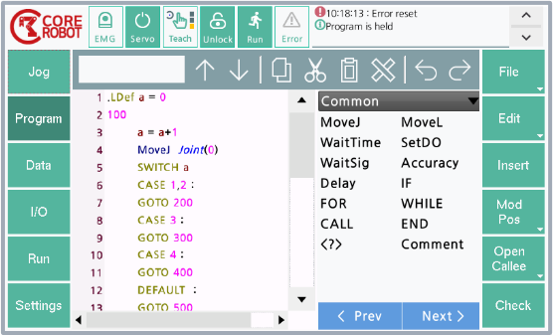

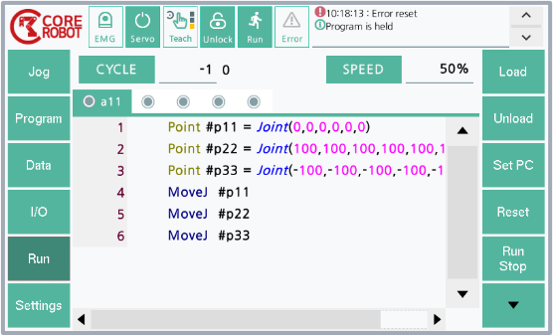

3. Programming

4. Run (Repeat)

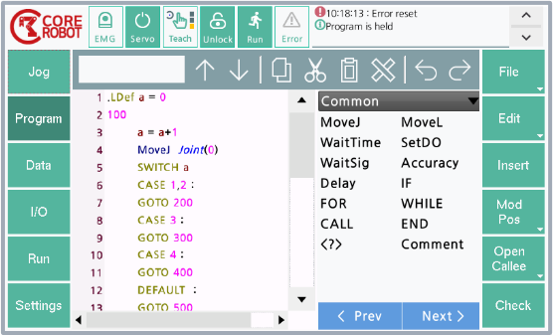

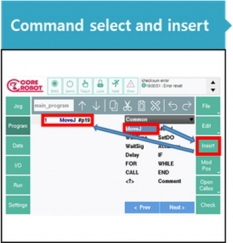

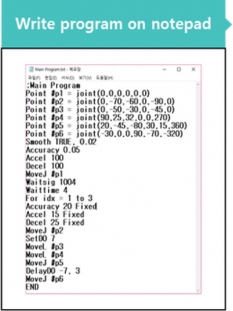

Robot Job Programming

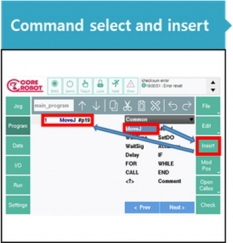

1. How to Create on Controller

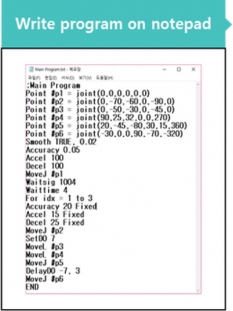

2. How to Create on PC

How it works

Example of 1-axis setting and operation DAINCUBE

Example of 6-axis robot and DRSC-HA setting and operationc DAINCUBE

Example of Robot language (CL Language) DAINCUBE

Example of DIO-32A setting and operation DAINCUBE

Q&A

Application Examples

Download

DMC-coreCon

Motion Controller

Motion Controller (DMC-coreCon)

Reduced Development Time - Immediate deployment with simple configuration, no programming required.

Custom Optimization - Supports development and application of customized robot kinematics.

Integrated Control - Unified management of diverse robots through a single UI.

Easy Expansion - API library enables integration with higher-level systems.

Broad Compatibility - Seamless integration with EtherCAT servo drives from various manufacturers.

Simplified Wiring - Minimizes complex wiring for easy installation and maintenance.

CoreSim - 3D Model-Based Simulator

Offline programming enables pre-verification without actual equipment: collision detection / cycle time analysis / layout validation. Reduces training, testing, and maintenance costs.

CoreStudio – A More Powerful and Smarter Development Environment

CL script IntelliSense, AI code recommendations, and automation. Remote debugging and data management. An all-in-one solution for efficient development and rapid validation.

Custom Kinematics

Daincube's motion controllers support not only standard robot kinematics (Cartesian, Serial, SCARA, Delta, UR6, etc.), but also custom kinematic structures desired by customers.

Virtual Axis

Virtual axes can be created independently of physical axes. Complex multi-joint structures can be integrated into simple logical axes → Simplified control algorithms.

Hint Function

In multi-arm environments, select operation modes by specifying constraints for each arm as Custom Hints (e.g., maintain relative angle, maintain specific position). This enables predictable and stable control of complex multi-joint structures.

Cofactor (Linkage Axis Compensation)

Mathematically compensate mechanically linked axes.

Vibration Reduction Function

The Daincube motion controller provides various vibration suppression functions to reduce residual vibration in equipment occurring within precision motion control environments. These functions support stable performance when robots and automation equipment perform high-speed, high-precision operations.

Smooth (S-curve)

가속/감속 구간을 S-curve로 매끄럽게 만들어 충격·잔류진동 완화

Input Shaping Filter

명령입력을사전보정해 공진주파수(구조진동) 성분을최소화

Table Profile

시간-속도 테이블 기반의 사용자 정의 프로파일로 공정/구조 특성 최적화

Controller Advantages

Logging

- System / Operation / Driver Log

- TCP / MCProtocol / Modbus Communication Log

- NVRAM Debug Logging → Safe Recovery after Power Failure

Diagnostics

- EtherCAT Diagnostics: Cycle/Shift/Sync, Lost Frame, Working Count

- Slave Status / Bus Topology / Link Down Logging

- Axis Status: Servo On/Off, OP/Link Verification

Debugging

- Check Mode: Step-by-step safety verification

- Breakpoint & Watch View: Variable monitoring

- Debug Mode: Conveyor/Signal testing

- NVRAM Debug Logging → Safe recovery after power failure

Profile Analysis

- Chart Function: 5000-cycle recording/analysis

- Position / Velocity / Torque Comparison

- Frequency/Time Domain Analysis → Vibration & Tracking Error Verification

- Tuning · Performance Optimization · Anomaly Pattern Analysis

Simulation & UX

- The Dryrun feature enables safe and rapid pre-installation verification by executing program logic without driving actual equipment.

- Digital twin simulation integrated with 3D model-based coreSim enables pre-optimization of collisions, cycle times, and layouts.

- Custom UI API allows implementation of a customized UI reflecting the customer's identity.

Technical info

CPU

i.MX6Q:Quad 1.0GHz

Cortex-A9 Core (11500 DMIPS)

Display

HDMI 1.4

1920×1080 resolution

Mounting

Wall Mount, DIN Rail

Memory

DDR3 800MHz 1GB

OS

Embedded Linux 4.1.15

Real-time Linux (Xenomai) 2.6.5

Qt 4.8.7

Dimension

168x103x30mm

Storage

eMMC 8GB (MLC type)

MRAM 2MB (Option)

Interface

EtherCAT, Ethernet,

CAN, RS-485

Weight

500g

Setting & Configuration

1. Quick Setting

Select Robot Type

Driver Spec

Dimension

Work Range

Jog

2. Jogging (Teaching)

3. Programming

4. Run (Repeat)

Robot Job Programming

1. How to Create on Controller

2. How to Create on PC

How it works

Example of 1-axis setting and operation DAINCUBE

Example of 6-axis robot and DRSC-HA setting and operationc DAINCUBE

Example of Robot language (CL Language) DAINCUBE

Example of DIO-32A setting and operation DAINCUBE

Q&A

Download

DMC-L

Technical info

CPU

i.MX6Q:Quad 1.0GHz

Cortex-A9 Core (11500 DMIPS)

Display

HDMI 1.4

1920×1080 resolution

Mounting

Wall Mount, DIN Rail

Memory

DDR3 800MHz 1GB

OS

Embedded Linux 4.1.15

Real-time Linux (Xenomai) 2.6.5

Qt 4.8.7

Dimension

168x103x30mm

Storage

eMMC 8GB (MLC type)

MRAM 2MB (Option)

Interface

EtherCAT, Ethernet,

CAN, RS-485

Weight