Elevated Safety Standards Mandate Intelligent Safety Solutions

The global trend towards the high-speed, advanced automation of manufacturing floors and the increasing prevalence of human-robot collaboration necessitates continuously strengthening regulations and standards for worker safety. This shift is redefining the Safety Controller from a simple emergency stop device into the core of intelligent, predictive safety control.

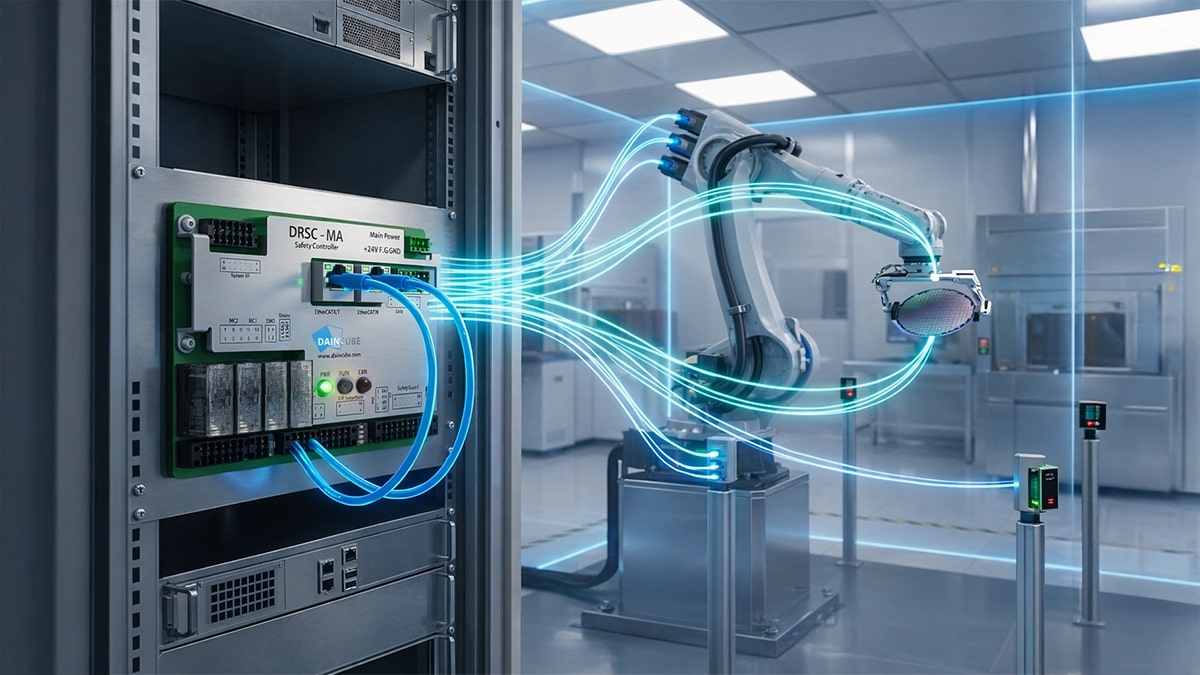

Today, the Safety Controller is no longer just responsible for emergency stop functions; it is the core of an Intelligent Safety Solution that predicts and responds to risks in real-time, directly linked to equipment performance. While traditional safety systems relied on physical barriers such as emergency stop buttons or safety fences, the latest Safety Controllers enable more flexible and efficient safety management by analyzing sensor data in real-time and precisely controlling robot movements. Therefore, adopting a globally certified Safety Solution is not merely about fulfilling corporate legal obligations; it is an essential strategy for ensuring production system stability and securing global competitiveness.

Core Technological Features of the DAINCUBE Safety Controller

- Real-Time Safety Monitoring : This unified architecture ensures perfect Safety-Motion Synchronization. Safety sensor signals and motion control are synchronized at the frame level, enabling immediate and precise safe stopping functions (e.g., STO – Safe Torque Off, SS1 – Safe Stop 1) upon hazard detection.

- Hardware-Based Safety Logic :The DAINCUBE Safety Controller implements the Safety PLC Logic in hardware, featuring a structure where safety logic is automatically executed simply by connecting the safety switches via cable, without the need for complex software programming. Furthermore, it adopts a multi-layered safety monitoring structure designed to ensure that safety functions are maintained even in the event of a single fault, achieved through the processing of redundant safety input signals such as Dual Emergency Stop and Dual Enabling.

Proven Safety: International Compliance and Global Competitiveness

The DAINCUBE Safety Controller has proven its technical reliability and global competitiveness by meeting stringent International Safety Standards.

- International Safety Standards Compliance: The DAINCUBE solution complies with demanding International Safety Standards such as ISO 13849-1, securing the highest level of Safety Performance Level required in advanced manufacturing environments.

- Ensuring Global Reliability: These international certifications validate the DAINCUBE Safety Controller as a global standard, guaranteeing consistent safety performance across manufacturing environments worldwide.

Advantages for SIs / Manufacturers: Speed-to-Market and System Reliability

The DAINCUBE Safety Controller goes beyond being a simple safety component, offering key advantages that enhance clients' business competitiveness.

- Certification Leverage: Robot manufacturers and System Integrators (SIs) can directly leverage the international safety certification results already acquired by the DAINCUBE Safety Controller for their equipment’s final certification process.

- Faster Market Entry: This drastically reduces the time and cost required for safety certification, enabling clients to launch new products faster than competitors and secure valuable business opportunities.

- Enhanced System Reliability: The perfectly synchronized Safety Control System improves equipment reliability, helping clients’ machinery achieve higher valuations in the global market.

Safety Controller: The Key Global Strategy for Synchronizing Productivity and Safety

The DAINCUBE Safety Controller is not just a device for regulatory compliance; it is a core component for securing global competitiveness. The real-time Safety-Motion Synchronization technology, enabled by EtherCAT integration, ensures worker safety while maintaining maximum equipment uptime and productivity.

By delivering solutions fully compliant with International Safety Standards, DAINCUBE remains a trusted partner for clients seeking sustainable growth and building next-generation Intelligent Manufacturing environments.