Robot Control Platforms Confront the OT/IT Integration Challenge

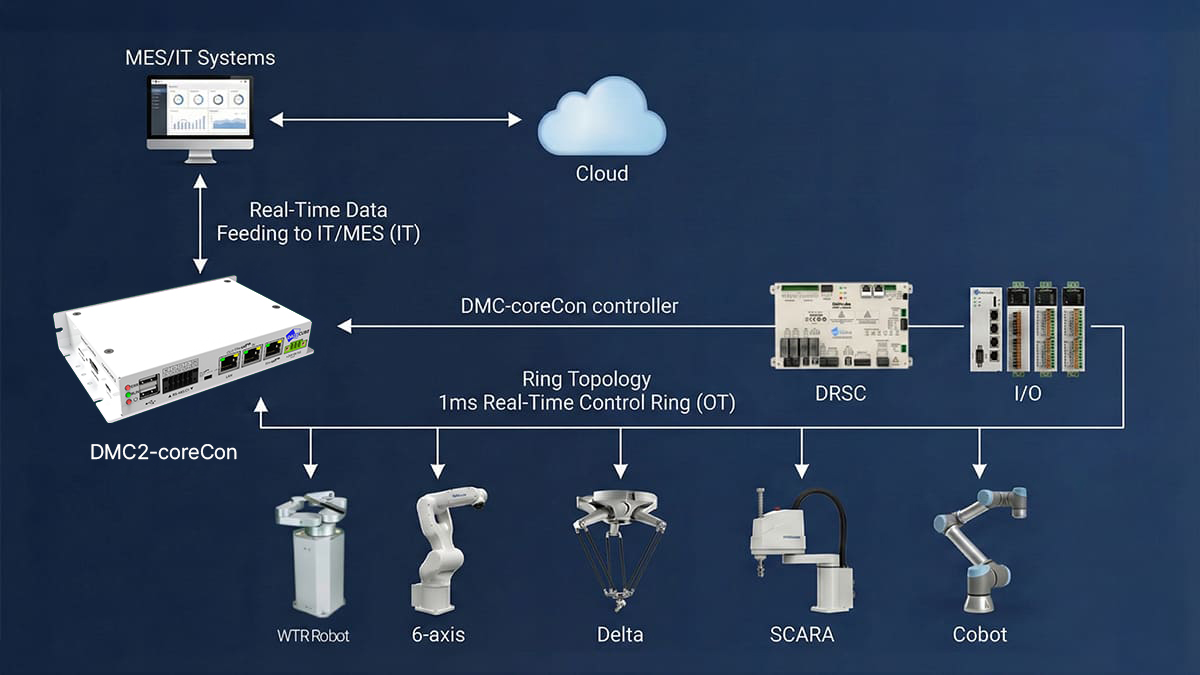

The accelerating adoption of diverse robot types in industrial settings—including multi-axis, Delta, SCARA, and collaborative robots (cobots)—has made it essential to control all of them from a single, unified platform. Moreover, the success of the Smart Factory depends on resolving the data silos between OT (Operational Technology) and IT (Information Technology), and the ability to integrate production data in real time. Traditional control methods faced limitations in reliably performing high-speed control while simultaneously collecting and transmitting data.

To address these challenges, Daincube developed ‘DMC2-coreCon,’ , an advanced controller that adds innovative Dual EtherCAT capabilities on top of the powerful robot control foundation of coreCon. This enables both enhanced robot control performance and seamless Smart Factory data integration within one system.

Dual Controller DMC2-coreCon: Control Hub (Master) and Data Hub (Slave) in One System

The DMC2-coreCon features a Dual Controller structure that allows a single piece of hardware to perform two independent EtherCAT functions, functioning as both a robot controller and a data integration hub.

- Lower-Level (Master) Role: Robot ControlBased on coreCon’s technology, DMC2-coreCon operates as a Master on the subordinate EtherCAT network, delivering high-speed, real-time control of servo drives, I/O modules, and other lower-level devices.Built on Real-Time Linux (Xenomai), it maintains a deterministic 1ms cycle time, enabling precise motion and optimal OT-level performance.

- Upper-Level (Slave) Role: Data IntegrationAt the same time, DMC2-coreCon acts as a Slave on the upper-level network, directly connecting to higher controllers (such as TwinCAT) or MES/IoT platforms. This creates a real-time data pipeline that transfers detailed control data from the subordinate Master to the upper system without delay.

Through this unique structure, DMC2-coreCon unifies networks from equipment level to factory level into a single EtherCAT architecture, achieving both high-speed motion control and real-time data feedback concurrently.

The Complete Data Flow: Real-Time Visibility via MES/IoT Integration

DMC2-coreCon integrates the equipment, line, and factory levels into a single EtherCAT network, enabling data-driven quality management through real-time data linkage.

- Practical Effects of Direct Linkage: The direct linkage of EtherCAT data to the upper system enables simultaneous real-time control and analytical capabilities—collecting, analyzing, and providing feedback on process data instantaneously. For example, real-time data (robot torque, position error, temperature) can be immediately monitored and analyzed by the superior MES. This facilitates data-driven decision-making, such as detecting anomalies before equipment failure or instantly responding to minor process changes.

- Securing Smart Factory ‘Visibility’: The real-time data collected ensures high Visibility into the production floor status, enabling data-driven quality control and production optimization. Ultimately, this maximizes production efficiency and boosts quality reliability.

Through this unique structure, DMC2-coreCon unifies networks from equipment level to factory level into a single EtherCAT architecture, achieving both high-speed motion control and real-time data feedback concurrently.

Strengths of Daincube’s coreCon: Diverse Robot Support and High Performance

The coreCon platform—the foundation of the DMC2-coreCon—simplifies complex robot control environments while guaranteeing premium control performance.

- Diverse Kinematic Support: Real-TiIt supports various robots—multi-axis, Delta, SCARA, Cartesian, and cobots—under the same unified UI/UX, maximizing development and operational efficiency. By supporting all robot types on one platform, clients save time and cost on software rebuilding when changing equipment.

- me OS Base: The fast response time based on Real-Time Linux (Xenomai) ensures the deterministic stability essential for high-speed control environments. This is the core technological foundation that maintains the 1ms cycle time without deviation.

Daincube's Vision for Smart Manufacturing

With the innovative DMC2-coreCon Dual EtherCAT Controller, Daincube has completed its strategy for solutions “from control to data integration.” The DMC2-coreCon is the optimal solution that simultaneously satisfies the key requirements of the future Smart Factory environment—high-performance control in the OT (Operational Technology) domain and real-time data integration in the IT (Information Technology) domain—within a single platform.

Based on this powerful technology, Daincube helps clients achieve data-driven quality control and production optimization. DMC2-coreCon is evolving beyond a simple controller into an intelligent solution that sets a new standard for intelligent manufacturing. This evolution will play a key role in positioning Dain Cube as an essential partner driving the sustainable growth of its clients.