The Heart of Advanced Automation: Daincube's Full-Stack Technology Platform

In the era of the 4th Industrial Revolution, the industrial robot and automation equipment industry demands three core elements: precision, high-speed communication, and safety. Specifically, the Motion Controller that governs robot movement and the Teach Pendant used to operate the robot are key components directly linked to equipment performance.

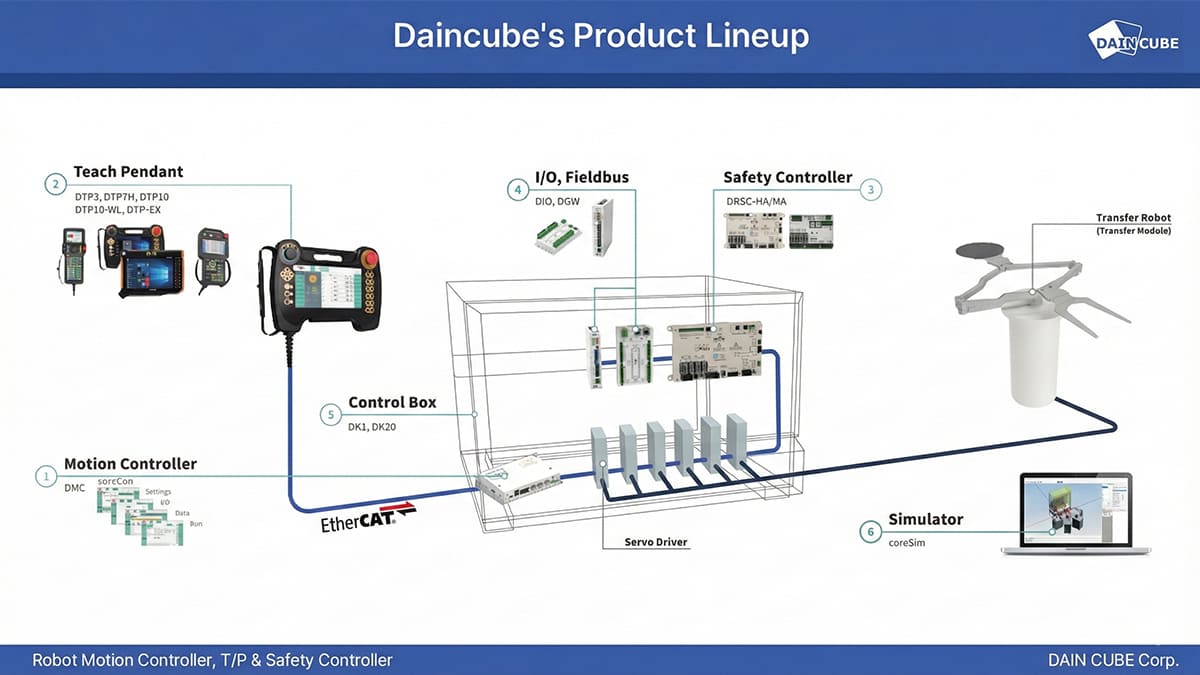

Daincube is challenging global leaders from Germany and Japan by securing full-stack control capabilities that integrate everything from hardware design to software algorithms, built upon its exclusive EtherCAT Master technology and an Real-Time OS (RTOS) platform. This integrated capability forms the foundation of all control solutions Daincube provides and enabes optimized performance tailored to each client's equipment and process.

| Category | Daincube's Full-Stack Platform |

Competitors (Major Foreign Companies) |

|---|---|---|

| Control Platform Architecture |

EtherCAT Master, high-performance RTOS-based platform | Mix of various industrial standards and proprietary protocols (EtherCAT, Mechatrolink, CC-Link, etc.) |

| System Integration Scope |

Integrated HW/SW development for Teach Pendant, Motion Controller, and Safety Controller | Module-based product offering (H/W or S/W) and combination of Motion Controllers, Servo Drives, HMIs, etc. |

| Competitive Advantage |

High performance, real-time control, flexibility in customization | High standardization, extensive field references |

| Key Product Line-up |

Teach Pendant, Motion Controller, Safety Controller | Motion Controller, Servo Driver, HMI, PLC, etc. |

Daincube's Robot Control Solution Lineup: A Combination Technology and Performance

Based on its full-stack technology, Daincube has established a core control solution portfolio that satisfies the requirements of major domestic and international automation equipment and robot manufacturers.

◼ Teach Pendant

Teach Pendant is the essential HMI device for programming and operating industrial robots. Daincube's Teach Pendant can implement customized UI/UX based on various platforms and possesses high durability for stable operation even in extreme working environments. It has been applied to diverse reference cases, ranging from domestic and international display/semiconductor equipment to welding equipment in the shipbuilding sector, demonstrating verified technological reliability and safety.

◼ Motion Controller

Motion controller is the "brain" responsible for a robot's precise movement and high-speed synchronous control. By internalizing EtherCAT Master technology, it delivers optimized performance for multi-axis synchronous control. Its RTOS-based foundation allows for accurate control of even the finest movements of the servo motor. It has been widely applied in automation equipment for core manufacturing processes in the domestic semiconductor, display, and automotive industries, and its high-precision control capabilities are recognized.

◼ Safety Controller

Complying with international safety standards, safety controller is an essential safety device that detects and controls dangerous situations that may arise during robot and equipment operation. Daincube's Safety Controller is fully integrated into the control system, providing fast and reliable safety functions. Furthermore, it contributes to worker safety and equipment protection by meeting the stringent safety criteria required in advanced manufacturing environments.

Full-Stack Technology and Trusted Success: Daincube's Partner Ecosystem

By controlling the entire technology stack from low-level hardware design to high-level software algorithms, Daincube has earned its place as a trusted, successful partner for leading automation and robot manufacturers worldwide

- Teach Pendant Key Partners: Applied Materials, LG Display, LS ELECTRIC, Robot & Design, CIMAX, NineBell, Hanwha Ocean, HD Hyundai Samho Heavy Industries, etc.

- Motion Controller Key Partners: Samsung Electronics (SEMES), Raontech, SFA, T-Robotics, Woojin Plaim, Hanyang Robotics, Now Robotics, etc.

These extensive collaborations prove the technical dominance and market confidence in Daincube’s solutions, highlighting its capacity to deliver fully optimized systems for demanding manufacturing environments. A key differentiator is Daincube's proprietary control platform, which enables swift and in-depth customization to meet specific client demands—a level of flexibility that foreign, standardized solutions often cannot match.

Pioneering the Future of Global Robotics Through Sustainable Technology Innovation

Daincube is positioned as an optimized partner for achieving client’s automation goals, expanding its competitive edge in the global robot control sector based on its proprietary full-stack control technology. Through continued R&D investment, Daincube will lead future industrial robot technology and establish new standards in the global automation market.